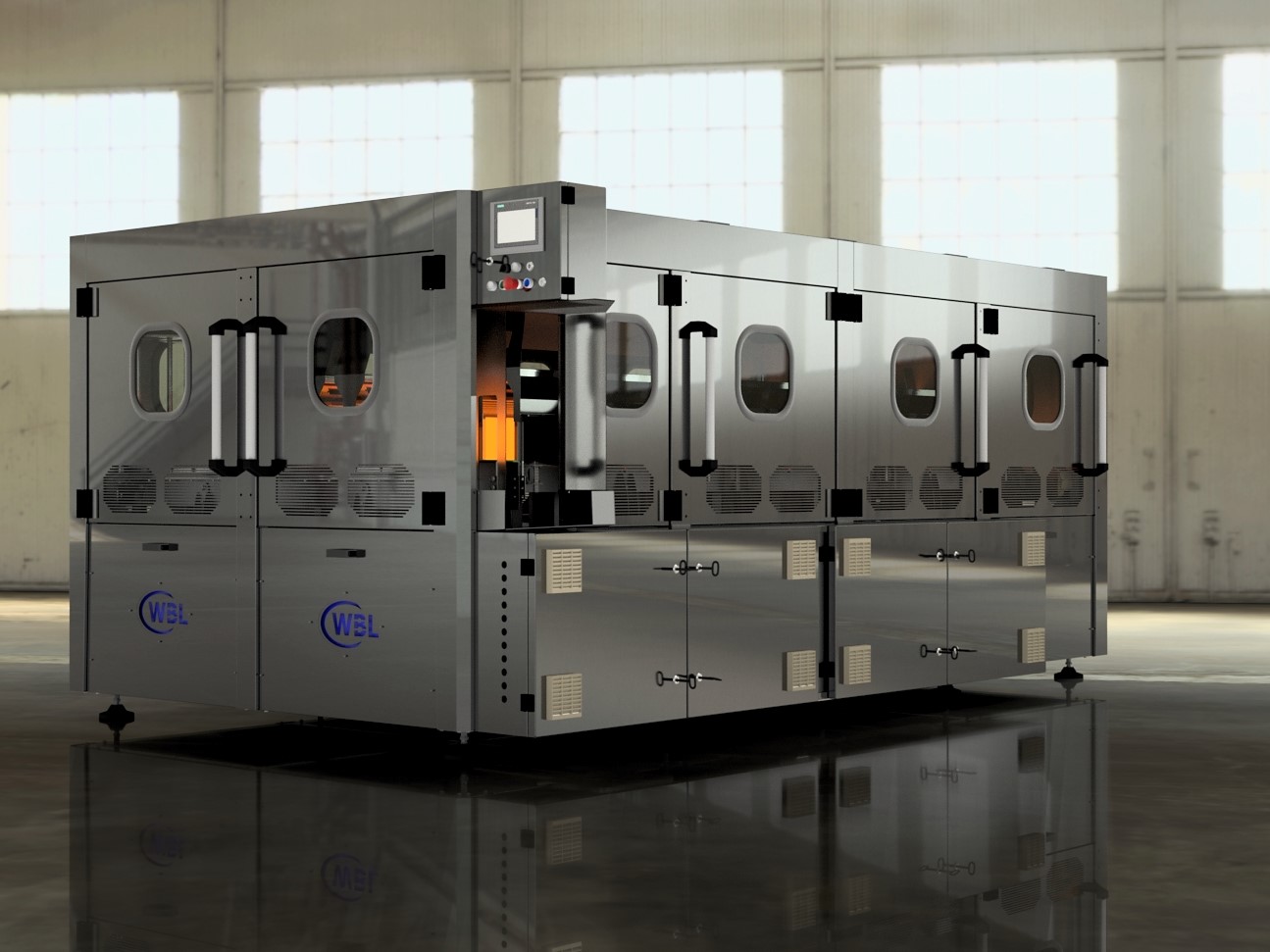

CAD-X

RADIANT DYNAMIC CONDITIONER.

Innovation has begun

TECNOLOGIA BREVETTATA

The WBL model is an absolute innovation in the field of bottle conditioning because it does not require the use of water. This major innovation allows for the elimination of condensation after cold filling with a halved cycle time, plus considerable energy savings and the absence of problems such as algae or limescale formation.

No Water

Device

The product is brought to room temperature by means of radiant panels.

Water usage is eliminated.

The bottle is always dry and the machine always clean, preventing the formation of limescale, algae and bacteria.

Advanced Catalytic

Technology

The catalytic system has 98.5% efficiency as all energy is converted without losses. Thanks to this direct conversion, there is no longer any plant engineering burden on the customer and management costs are reduced.

Significantly

Reduced Dimensions

With this conditioning technology, the time required for the process is reduced by 50% compared to devices that work with water. In this way, the machinery footprint is drastically reduced and line integration is significantly facilitated.

Stationary

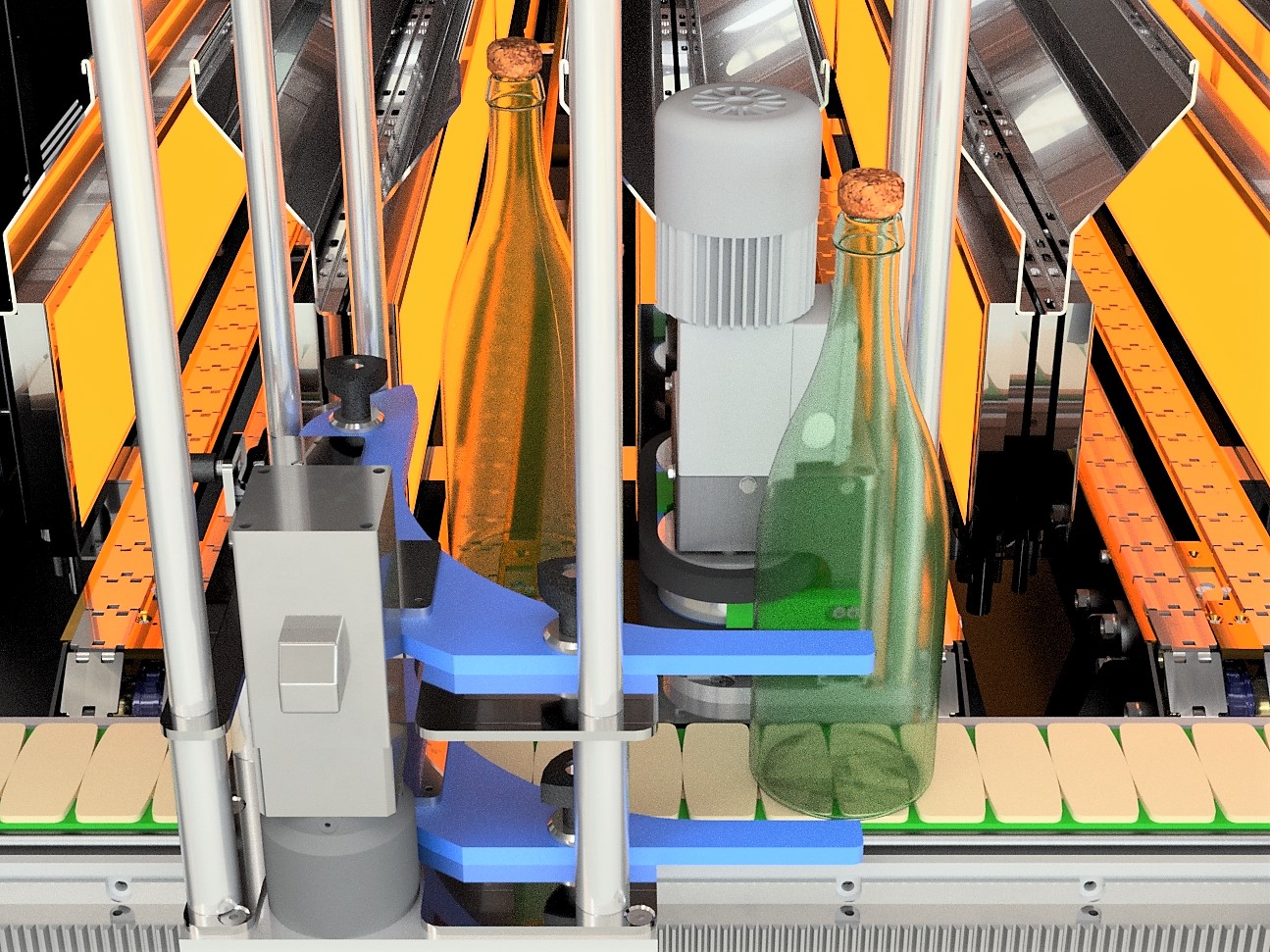

Treatment

It is the first machine in the world with stationary product treatment. The bottles don’t touch each other, contact noise is eliminated, energy is dosed onto the stationary product, therefore there is no dispersion. The bottle is no longer subject to instability risks.

Dynamic

Accumulation System

WBL has equipped this type of machine with a smart bottle sorting system.

The lanes are independent – if a problem occurs on one of them, the others will continue to work autonomously, avoiding machine downtime.

Fifo

Device

The full bottle conditioner designed is a FIFO (first input first output) management machine that guarantees lot traceability and residence time during the process. This gives us a guarantee of treatment uniformity.

Bottle

Always Dry

The elimination of water as a treatment fluid results in having an always-dry bottle that does not require an additional drying phase after conditioning. This saves space and energy.

Contactless

Filling

The studied method of bottle sorting in the machine has produced step-wise lane filling, i.e., without contact between bottles. Related noise is eliminated and all lane adjustment to keep bottles stable is eliminated.